Experience in implementing the most complex and innovative galvanic processes since 1969

Zincatura Nazionale srl is a company specialized in barrel electrolytic galvanising treatments in the most complex and innovative galvanic processes.

Zincatura Nazionale was founded in 1969 by Burattin Pietro and is now run by his sons Barbara, Luca and Roberto.

5

production lines

20K

Square metres of extended production area

150

Tonnes of material processed per day

Quality

High production standards

ON TIME

Speed of delivery

ECOGREEN

Respect for the environment

TAILOR-MADE

Products on request

Treatments

We carry out a wide range of treatments on ferrous small parts.

We have a packaging department where the material is packed and we provide a delivery and collection service.

Treatment

of zinc nickel

Acid and alkaline

zinc plating

Zinc

flake

Dehydrogenation

& other services

5

production lines

Our plants perform barrel or basket work on ferrous small parts and our technicians are capable of proposing solutions to any customer request.

3

LINES

of electrolytic cold galvanising in barrels

1

LINE

of zinc

nickel

1

line

of lamellar

zinc

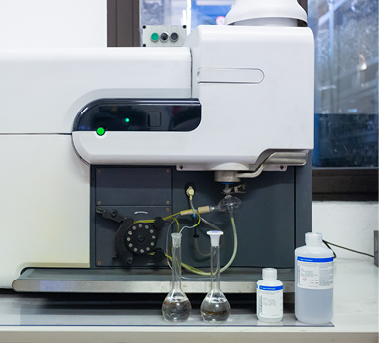

QUALITY

IN THE FIRST PLACE

IN-HOUSE ANALYSIS LABORATORY

Zincatura has an in-house testing laboratory with extensive instrumentation for process and product control.

2

INSTRUMENTS

FISCHER X-RAY

1

SALT SPRAY

CHAMBER

1

FRICTION COEFFICIENT VERIFICATION TOOL

OUR

CERTIFICATIONS

Ever mindful of processes organised according to the rules in order to work productively and more efficiently in an environmentally friendly manner, we have implemented the ISO 9001:2015 quality and ISO 14001:2015 environmental management systems.

AN ECOGREEN

COMPANY

Sensitive to the environmental aspect, we work to comply with all relevant regulations. We have an internal Environmental Policy, as well as being ISO 14001:2015 certified. We have invested in new technologies that enable us to produce electricity and heat to cover 60% of the company's daily needs, thus reducing environmental pollution.